The gray concrete slab may have some use, but it will not likely impress anyone. We believe that your property can be treated to something better. One of the most effective ways of giving the patio, for example, a makeover without the hefty cost of tearing down what is already there is concrete staining. It gives the patio depth and elegance and an expensive look without the hefty price tag.

Over the years, we have fixed enough homemade disasters to know that staining isn’t just a process of painting. Concrete is a very porous and harsh surface to work with. If you cut corners on this process or skip a step, your stain will start peeling, fading, or becoming spotty within a year’s time.

Our crew, when working on a staining project, has a set procedure in place to ensure that our finish will last for years to come. This is a look into how we achieve a professional finish at Bill’s Custom Concrete. Whether you want to learn about the sidewalk repair cost or our staining services, get in touch today!

Surface Preparation is Not Negotiable

The key part of what we do is what happens even before we open the stain. If the concrete isn’t spotlessly clean and ready to absorb our stain, the stain won’t stick. First, we remove everything from the patio and sweep away any loose debris. Next, we clean the patio using a top-of-the-line degreaser and brush away any dirt and oil spots.

With the surface clean, we can start the repair of the cracks. How do you stain a concrete patio? Staining a crack means they will not be hidden, but will actually be highlighted because the stain will collect inside the crack. To remove these defects, concrete filler needs to be applied.

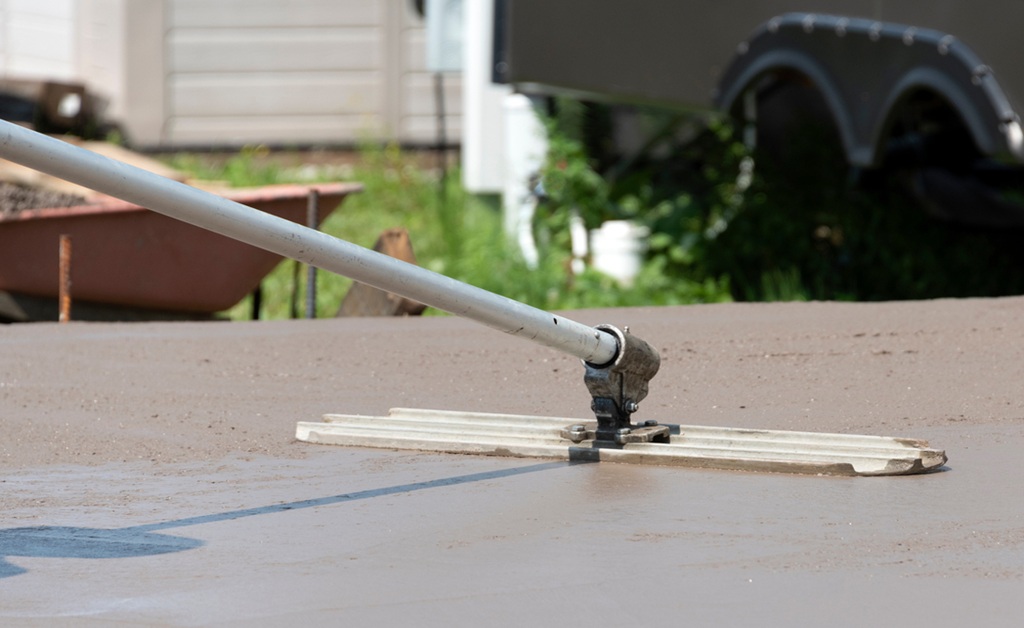

The last step of patio preparation could either be acid etching or grinding. This will help the concrete pores open up so that the concrete patio stain adheres to the surface of the concrete rather than just sitting on top of it. The patio needs to be washed and dried.

Choosing the Right Type of Stain

We help our customers choose which type of stain they should apply. There are two types of stains. These stains can be either acid-based stains or water-based stains. This choice solely depends on the customer and the design they want to create. Acid-based stains react chemically with the minerals present in the concrete. These reactions cause earthy colors of tans, browns, and terracottas.

With water-based stains, there is more of a coating process involved. The colors are poured into the concrete pores with no reaction whatsoever. This is because there is a much larger array of colors available, such as bright blue, green, and even opaque grays. In a situation where an entire patio needs to be stained with the same color, we would recommend using water-based stain.

Applying the Stain for Maximum Effect

Then, when it’s time to apply the stain, we have found that using the pump sprayer gives us the best results. We divide the area and make our way around, making sure that we don’t get any lap marks, which would be areas that accumulate the stain. When working with the acid stain, we apply the stain and then scrub the liquid onto the surface.

Ultimately, it is always recommended to go for thin coats and not a thick coat. This is to ensure that there is no pooling and to be able to control the amount of color that we want to achieve. At all times, safety is the priority in such a procedure. We use eye protection, gloves, and boots, especially when dealing with the acid stain.

Once the stain is applied, we then wait for it to dry according to the time recommended by the manufacturer, which is at least 24 hours. Stained patio concrete can dramatically improve curb appeal.

Sealing to Protect the Investment

The process is not finished until the sealer is applied. An unsealed patio with staining would be much the same as if a vehicle was uncoated, since either the sun or the water will eventually damage it. This is why we apply a clear and good-quality sealer that protects it from water, grease, and the sun. Choosing the best stain for concrete patio projects will ensure a lasting finish.

It comes in a variety of gloss levels, from flat to very high gloss. We would normally recommend a solvent-based acrylic sealer for outdoor patio floors because it breathes well and is very durable. It’s very easy to maintain after that. We tell our customers to sweep the patio clean and reapply a new coat of sealer in a few years to keep it looking its color.

A Lasting Transformation

The process of staining concrete patios is something that cannot be done in a rush. Why? Because it is a process that also takes skill and patience on the part of the technician. However, with the right technique, a concrete patio that is dull and unattractive can be made into a beautiful feature of the house. If you’re searching for the right stain for concrete patio renovations, always consult with the professionals at Bill’s Custom Concrete for the best results!